Shower heads are available in different materials such as plastic, stainless steel, brass, or chrome-plated metal. They may incorporate additional features such as water-saving technologies, built-in filters to remove impurities, anti-clog mechanisms, or LED lights for visual appeal.

The manufacturing procedure of a shower head can vary depending on its design, materials, and production scale. However, here is a general overview of the typical steps involved in manufacturing a shower head:

1. Design and Development: The process usually begins with the design phase. Engineers and designers work together to create concepts and detailed designs for the shower head, taking into account factors such as functionality, aesthetics, and cost.

2. Material Selection: Once the design is finalized, the appropriate materials for the shower head are selected. Common materials used for shower heads include plastic, stainless steel, brass, and chrome.

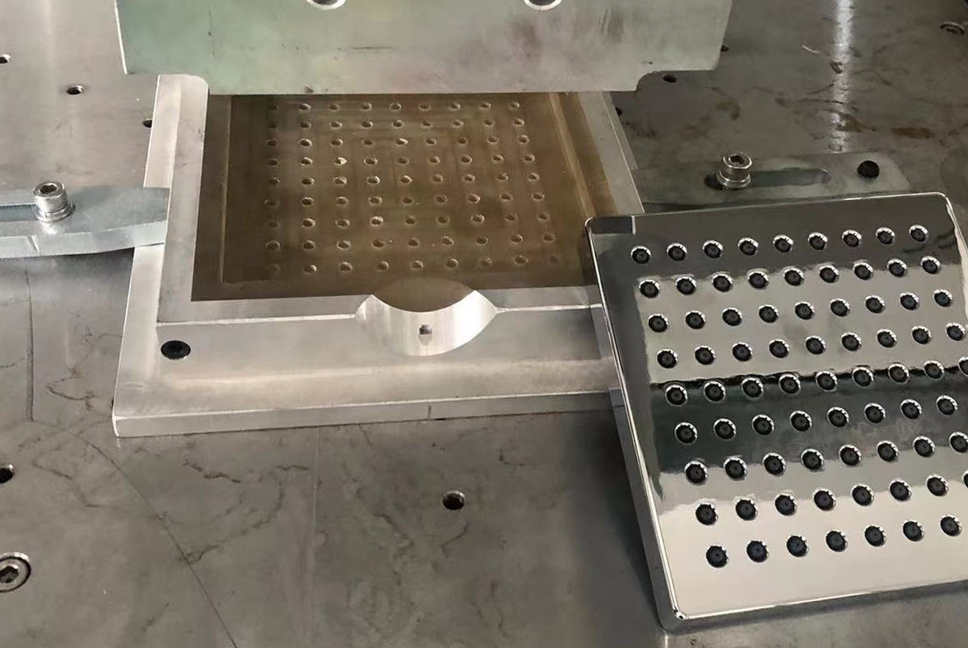

3. Molding or Casting: If the shower head housing is made of plastic, it may be produced through injection molding. For metal shower heads, processes such as die casting or machining may be used to shape the components.

4. Surface Finishing: The shower heads may undergo surface finishing processes to improve their appearance and durability. This could involve processes such as polishing, plating (e.g., chrome plating), or powder coating.

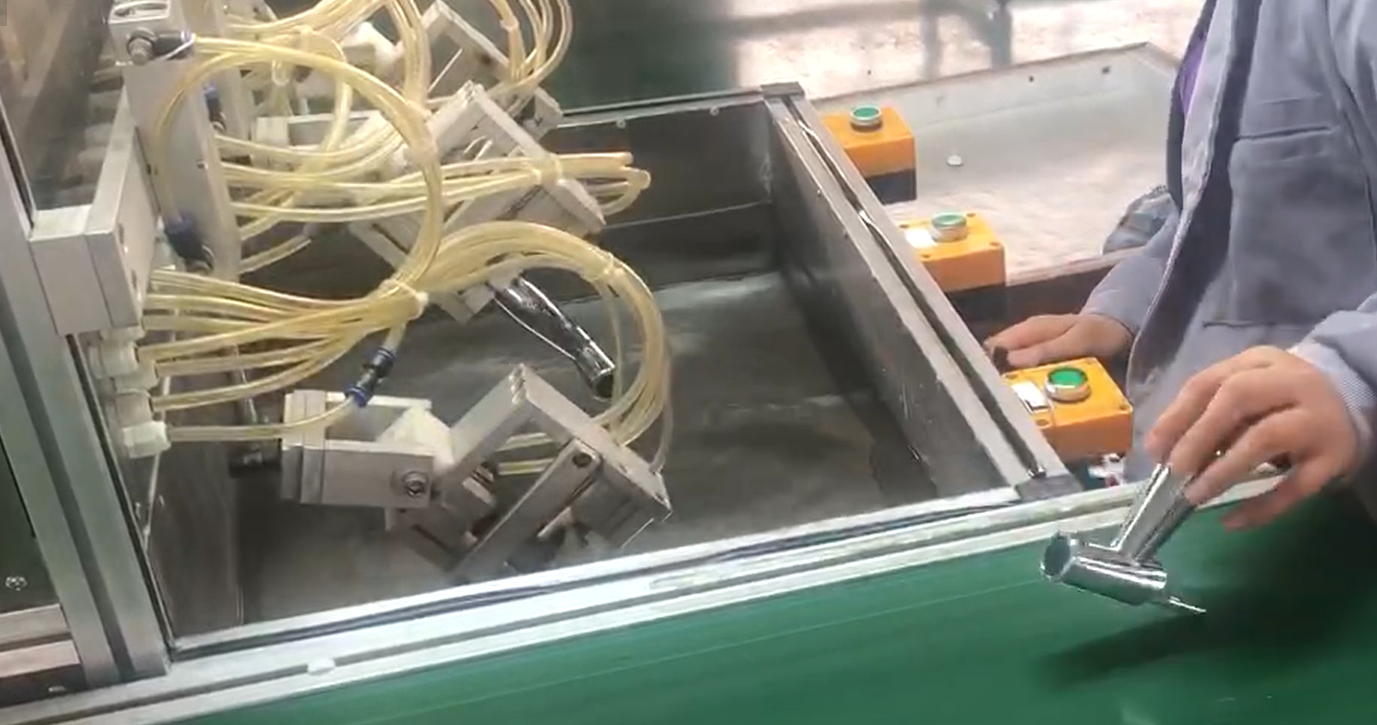

5. Component Assembly: Various components of the shower head, such as the housing, nozzles, valves, and handles, are assembled together. This may involve manual assembly, automated assembly lines, or a combination of both.

6. Quality Control: Throughout the manufacturing process, quality control checks are conducted to ensure that the shower heads meet the specified standards. This may include dimensional checks, pressure testing, flow rate testing, and visual inspections.

7. Packaging: Once the shower heads have passed quality control inspections and surface finishing processes, they are packaged for shipping. Packaging may include labeling, instructions for use, and protective packaging materials to prevent damage during transit.

Alothomes’s shower head throughout several stage of the manufacturing process, adherence to quality standards, efficiency, and safety are paramount to ensure the production of high-quality shower heads that meet customer expectations.

We welcome all customers to visit our factory with the highest level of hospitality, allowing you to experience our high-quality service